NEWS:Description of Mechanical Process Methods

8864

reads

“Manufacture” – The literal meaning is “to make manually”. However, the capabilities of people’s hands are limited. After the Industrial Revolution, machine tools have been subsequently developed and ever since evolve and advance endlessly.

Until nowadays as the manufacturing industry applies new technologies such as Computer Numerical Control (CMC), 3D Processing in coordination with CAD/CAM software programs, high-speed spindles, improved precision of machine tools, as well as developments of hybrid turning and milling machines, tooling technologies and new materials, more advantageous manufacturing methods have been developed, enabling reduced production costs and magnificent quality improvements of products.

The meaning of manufacture is to yield the product via Process Procedures that make changes in the appearance. The product is resulting from various Process Procedures. There are numerous Processing methods. Traditional processes are divided into cutting process and non-cutting process :

▶ Traditional Processes

Cutting Process :

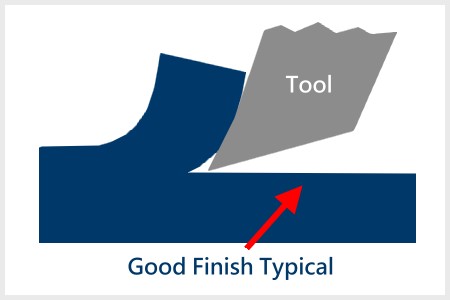

Mechanical processes such as lathe, mill, drill, shear, plane, bore, pull, and grind are cutting processes. Understanding by the word, the process involves shaping and forming the product using tools (cutter). The product is accomplished by removing small chips from the material to form the required appearance. Cutting off small chips is the key principle of a cutting process, therefore we need to thoroughly understand the principle for cutting metals.

The cutting principle:

Chips are formed with the workpiece undertakes shearing and cutting actions of the tool.

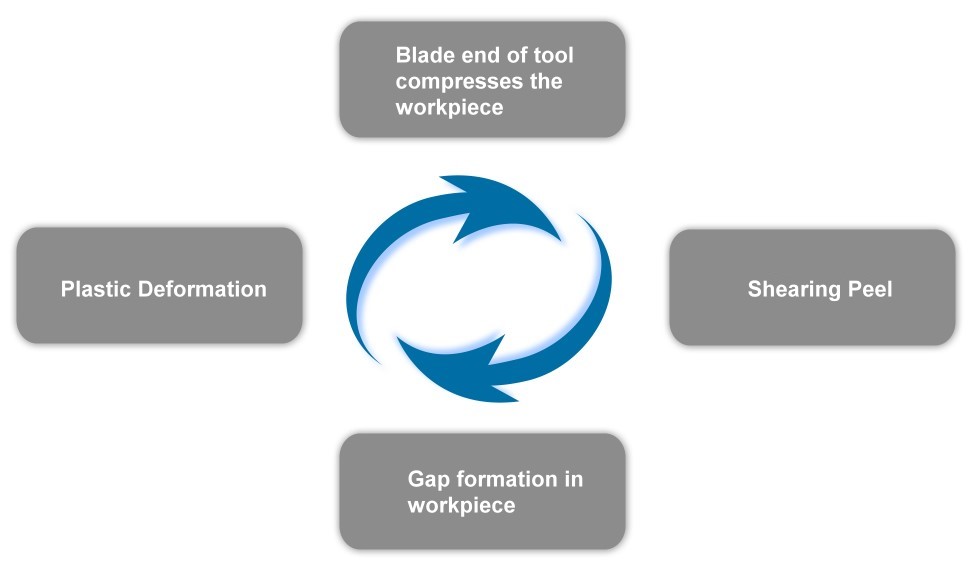

▶ Cutting Mode

Cutting Mode :

Compression → plastic deformation → gap formation → cut off (cycle repetitively).

Non-cutting Process :

Casting, Forging, Extrusion, Powder Metallurgy, Rolling, Punching, Cindering, Hot Pressing, Welding, etc.